Steve, well done.

There are two things that come to mind when looking at the picture.

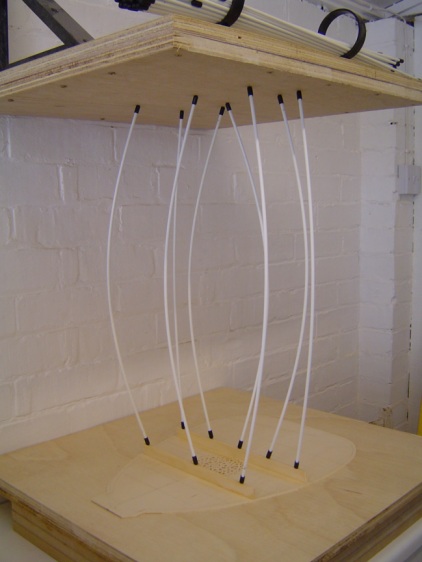

It looks like you have used melamine for the top and bottom boards. Is that so? You may find that the surface is very slippery and your rods may not "bite" into the surface very well. If you have some other board kicking around, I would switch to something a little "rougher" or just add a second board of a different variety, even basic plywood for the top will be fine, but you really want a surface that will hold the dish in place when you start adding pressure, the whole thing could "explode" out of there and you wouldn't want that.

If the plates are some other type of material that is not slippery, well just disregard all of that  . .

As others have said, there is a lot of pressure on the top plate when you a gluing down a full set of braces, even on a back. I would add a layer on the top or if you don't have a piece to add, you can add some "braces" on the top side of the top. Use 1"x2" screwed to through the 3/4" plate to stiffen up the entire top plate. Make a simple + on the top will add a lot of stiffness and you will not see much flex in the plate at all.

That's it though (other than the pipe over the all thread which many others have noted).

|